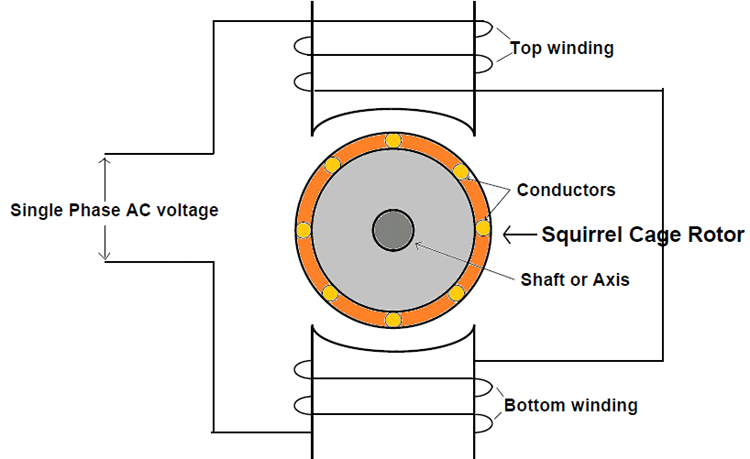

Single-phase motors use one AC supply, typically used for small appliances or residential applications. Three-phase motors use three alternating current (AC) power sources, They are commonly used in industrial applications such as pumps,compressors, conveyor systems, and large machinery.

Table of Contents

ToggleStarting Methods

A 750 W single-phase motor can have a starting current up to 4 times its rated current, around 30 A. The starting time is usually 1 to 3 seconds, with an efficiency close to 75%. A 5 kW three-phase motor typically has a starting current 6 times its rated current, about 60 A, but the starting time is only 0.5 to 1 second.

Autotransformer reduced voltage starting is especially suitable for medium-sized motors above 10 kW. By lowering the starting voltage, this method can control the starting current to within 3 times the rated current. For example, a 20 kW motor can reduce its starting current from 120 A to 40 A, and the autotransformer starting method can extend the equipment’s lifespan by approximately 15%.

A 50 kW three-phase pump with a soft starter can reduce the starting current from the traditional 300 A to 150 A, while extending the starting time to 15 seconds. The use of soft start technology reduces the average maintenance frequency of the equipment by 20%, saving about 10,000 yuan annually in maintenance costs.

Pole-changing starting has an efficiency of only around 60%. A single-phase motor with capacitor start can improve efficiency to 80%. In a medium-sized factory, equipment using direct-on-line starting with a total power exceeding 100 kW could cause a 10% voltage drop.

The starting torque of a single-phase motor is typically 1.5 times the rated torque, while the starting torque of a three-phase motor can reach 2.5 times the rated torque. For example, a 3 kW three-phase motor has a starting torque of 75 Nm, while a single-phase motor of the same power only has a starting torque of 45 Nm.

In the industrial sector, more than 70% of equipment uses three-phase motors, while in the household sector, over 80% of appliances use single-phase motors. The compressor power of a household air conditioner is typically around 1.5 kW, while the compressor power of an industrial cold storage often exceeds 50 kW.

The cost of direct-on-line starting equipment is about 50 yuan per kW, while the cost of soft starter equipment can reach 200 yuan per kW. In a factory with an annual electricity consumption of 500,000 kWh, using soft starter technology can save 5% of energy consumption, which is equivalent to 25,000 yuan in electricity savings annually.

Motor Efficiency

The efficiency of a single-phase motor typically ranges from 70% to 85%. For example, a 750 W single-phase motor consumes about 0.75 kWh of electricity per hour during operation, but the actual mechanical energy available is only 0.55 to 0.64 kWh. With 8 hours of operation per day, the annual electricity cost could exceed 219 yuan.

The efficiency of three-phase motors usually ranges from 85% to 95%. For example, a 10 kW three-phase motor consumes 10 kWh of electricity in one hour of operation, with usable mechanical energy between 8.5 to 9.5 kWh. In a factory running 24 hours a day, this could save about 20,000 yuan in electricity costs annually. A 1 kW single-phase motor at half-load operation has an efficiency of only around 60%, but at full load, the efficiency can reach 80%. If the load fluctuates often, it could increase actual energy consumption by about 15%.

The efficiency of three-phase motors typically ranges from 70% to 100% at rated load. For example, a 20 kW three-phase motor has an efficiency of 93% at a 14 kW load, and the efficiency remains above 90% at full load. This characteristic can save about 5% of operational costs annually.

The power factor of a single-phase motor generally ranges from 0.6 to 0.8, meaning that about 20% to 40% of the input power is wasted as reactive power. For example, a 1.5 kW single-phase motor could waste between 0.3 to 0.6 kWh of electricity every hour. Adding a capacitor compensation device at a cost of about 50 yuan per kW can improve efficiency by approximately 5%.

The power factor of three-phase motors typically ranges from 0.85 to 0.95. For instance, a 30 kW three-phase motor loses only 1.5 to 4.5 kW of reactive power per hour of operation, while a single-phase motor of the same power could lose up to 10 kW. This high power factor extends the motor’s lifespan by about 20%.

A 1 kW single-phase motor running for 3000 hours annually will consume 3000 kWh, with an efficiency loss of about 600 kWh, equivalent to a waste of 360 yuan in electricity. The efficiency loss of a three-phase motor is only 150 kWh, wasting just 90 yuan.

A three-phase motor running at a speed of 1500 RPM can achieve an efficiency of 94%, while a single-phase motor at the same speed only reaches an efficiency of 80%. For example, in a water treatment plant, using three-phase motors can reduce overall electricity costs by about 12%. After 2 hours of operation, the motor casing temperature of a single-phase motor typically reaches 60 to 80°C, while a three-phase motor under the same conditions only reaches 40 to 50°C. This improvement can reduce the failure rate by more than 30%.

Stability

A 1 kW single-phase motor may experience speed fluctuations of around 50 RPM during operation. In contrast, a 10 kW three-phase motor usually maintains a speed fluctuation of less than 5 RPM. A large compressor driven by a three-phase motor can reduce air pressure fluctuations to below 0.1 MPa.

When the load increases from 50% to 75%, the current of a single-phase motor can increase by more than 30% instantaneously. For example, a 750 W single-phase motor experiences about a 10% decrease in efficiency under load changes, with vibration typically reaching 0.2 mm.

Three-phase motors generally have a 20% to 30% higher load adjustment capability than single-phase motors. For example, a 15 kW three-phase motor will see a current increase of only around 10% when the load increases from 50% to 75%, and the vibration amplitude is just 0.05 mm.

When the grid voltage drops by 10%, a single-phase motor’s output power may decrease by more than 15%, and its efficiency drops to around 70%. In contrast, a three-phase motor’s output power reduces by only 5%, with efficiency remaining over 90%. This feature of three-phase motors can reduce downtime by about 25% annually. For instance, a single-phase motor operating for 2 hours may experience temperature fluctuations of 20°C, whereas a three-phase motor in the same conditions typically has temperature fluctuations within 5°C.

On an industrial production line, a three-phase motor can handle 30 starts per hour, with a failure rate below 5%. A single-phase motor’s starting frequency is typically limited to 15 starts per hour, and exceeding this can increase the failure rate to more than 10%. The average lifespan of a single-phase motor is around 8 to 10 years, while a three-phase motor can last 15 to 20 years. In an industrial plant, the annual maintenance cost of a three-phase motor is approximately 70% of that of a single-phase motor.

Noise

A 750 W single-phase motor running at full load produces an average noise level of 60 dB, with peak noise reaching 70 dB. A three-phase motor of the same power generates an average noise level of only 55 dB, with peak noise staying below 65 dB.

During startup, the noise of a single-phase motor increases by about 10% to 15%, reaching approximately 75 dB, and this peak noise lasts for 3 to 5 seconds. In comparison, the noise increase in a three-phase motor during startup is smaller, about 5%, with peak noise reaching 68 dB, lasting no more than 2 seconds. When the load increases from 50% to 80%, the noise of a single-phase motor may increase by over 20%, reaching 80 dB, while a three-phase motor’s noise fluctuation is usually kept under 10%, with peak noise not exceeding 70 dB.

A single-phase motor running at 50 Hz typically generates a higher noise level, averaging 65 dB, while running at 60 Hz increases the noise level to about 70 dB. In contrast, a three-phase motor operates at 55 to 60 dB at both 50 Hz and 60 Hz frequencies.

A 5-year-old single-phase motor can have a mechanical noise level about 15% higher than a new one, averaging around 70 dB, while a three-phase motor with the same usage typically experiences only a 5% increase, maintaining around 58 dB.

In high-temperature environments, a single-phase motor’s noise can increase by more than 10%. For example, in a 40°C working environment, the noise level might reach 75 dB, while a three-phase motor’s noise increase is typically only about 5%, with peak noise staying under 65 dB.

After 2000 hours of operation, the noise of a single-phase motor could increase by 5 to 10 dB, reaching 75 dB, while a three-phase motor’s noise increase is usually below 3 dB. A three-phase motor’s maintenance costs can save about 1000 yuan in annual repair expenses.

When installed on an unreinforced base, a single-phase motor may experience a 15% increase in noise due to resonance, reaching 80 dB, while a three-phase motor’s noise remains stable at 65 dB. This feature can reduce the overall installation cost of the equipment by about 20%. The low-frequency noise of a single-phase motor accounts for about 70% of the total noise. In a factory using single-phase motors, the noise reduction across a partition wall is only 5 dB, while with three-phase motors, the noise reduction can reach 10 dB.

Power Supply Requirements

A 1 kW single-phase motor requires a current of about 4.5 amperes during operation. The standard voltage for a three-phase motor is 380 volts or higher. A 5 kW three-phase motor typically requires a current of around 9 amperes during operation.

The startup current of a single-phase motor is usually 3 to 6 times the rated current. For example, the startup current of a 750 W single-phase motor can reach over 20 amperes, while the startup current of a three-phase motor is typically 2 to 4 times the rated current. In the case of a 15 kW three-phase motor, the startup current is about 40 amperes.

When the grid voltage drops by 10%, the efficiency of a single-phase motor may decrease by 15%, and the output power is reduced by 20%. Three-phase motors are more adaptable to voltage fluctuations, with efficiency only decreasing by 5% and output power reducing by less than 10% under the same conditions.

The power factor of a single-phase motor is typically between 0.6 and 0.8, meaning that 20% to 40% of the input power is wasted as reactive power. For example, a 1.5 kW single-phase motor wastes about 0.3 to 0.6 kWh of electricity per hour. The power factor of a three-phase motor is usually between 0.85 and 0.95, with reactive power loss typically ranging from 10% to 15% of the input power.

The power supply efficiency of a three-phase motor can be 20% to 30% higher than that of a single-phase motor. Under conditions of 40°C, the output power of a single-phase motor may decrease by 10% to 15%, while the output power of a three-phase motor typically decreases by less than 5%.

A single-phase motor may waste up to 25% of electricity when the load changes frequently. A three-phase motor, on the other hand, requires higher load balancing, with energy waste typically under 10%. An industrial conveyor system requiring three 10 kW three-phase motors to run simultaneously will need at least 9 power lines, which increases the cost by about 100 yuan per kilowatt.